Industrial Mixers

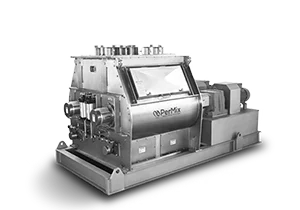

PerMix Vacuum Mixer & Dryer

Vacuum Mixing and Vacuum Mixers

The PerMix series of vacuum mixers and mixer/dryers function as high-efficiency turbulent mixing reactor-dryers.

Designed for versatility, they serve as high-speed mixer dryers, chemical reactors, or as combined dryer-reactor systems—delivering powerful performance in a single, compact solution.

PerMix Vacuum Mixers/Dryers

When performance, flexibility, and innovation matter, PerMix Vacuum Mixers/Dryers lead the way. Engineered for a wide range of applications—from pharmaceuticals and food & beverage to chemicals and nutraceuticals—these industrial mixers deliver exceptional results in both mixing and drying of powders, granulates, and pastes.

Why Choose PerMix Vacuum Mixers/Dryers?

PerMix offers all of its powder mixers in a vacuum mixer configuration, giving you the freedom to choose the ideal mixing equipment—such as a ribbon mixer, paddle mixer, plow mixer, fluidized zone mixer, or conical screw mixer—tailored to your specific process needs. By integrating vacuum technology, we ensure higher product quality and production efficiency.

Key Features

- Vacuum Technology

- Accelerates drying by efficiently removing air and moisture.

- Improves product stability by limiting oxidation and contamination.

- Supports delicate processing of heat-sensitive materials.

- Heating & Cooling Capabilities

- Jacketed designs for accurate thermal control across processes.

- Handles complex temperature-sensitive applications with ease.

- Custom Mixing Options

- Choose from multiple industrial mixer types—paddle, plow, ribbon, or screw mixers.

- Each setup ensures uniform mixing and consistent heat transfer.

- Durable Construction

- Available in 304/316 stainless steel, Hastelloy, titanium, carbon steel, and Hardox for abrasive duties.

- Sanitary finishes ideal for pharmaceutical and food-grade applications.

- Process Integration

- Vacuum loading simplifies material handling.

- Condensate recovery systems optimize solvent recovery and energy use.

Application Highlights

- Mixing powders, liquids, and granules under vacuum conditions.

- Drying heat-sensitive products with minimal product loss.

- Recovering solvents through condensation techniques.

- Producing nutraceutical-grade powder blends and capsules.

Industries We Serve

- Pharmaceuticals – Precision drying and blending of APIs and excipients.

- Food & Beverage – Creating shelf-stable formulations and custom blends.

- Chemicals – Managing reactive or sensitive powders and compounds.

- Nutraceuticals – Manufacturing vitamin-rich and functional powders.

Why PerMix?

PerMix combines engineering innovation with decades of experience to deliver world-class industrial mixing solutions. Whether you require high vacuum systems, gas purge functions, or fully automated PLC/HMI controls, our mixers are built to perform—efficiently, reliably, and affordably.

Ready to explore custom options? Contact PerMix today to discover how our vacuum mixers/dryers can elevate your production processes.

Working Principle

Working Principle of PerMix Vacuum Mixers/Dryers

PerMix Vacuum Mixers/Dryers leverage advanced vacuum mixing technology combined with mechanical agitation to deliver efficient, uniform, and contamination-free processing. Ideal for industries such as pharmaceuticals, food processing, chemicals, and nutraceuticals, these mixers ensure optimized heat transfer, precise drying, and consistent product quality.

1. Loading and Sealing

- Materials such as powders, pastes, or granules are introduced manually or via vacuum loading systems.

- The chamber is sealed to maintain a clean, oxygen-free vacuum environment, ideal for sensitive or reactive compounds.

2. Mixing Action

- Mechanical mixing is achieved with your selected agitator:

- Ribbon & Paddle Mixers: Best for gentle, thorough blending.

- Plow Mixers: Ideal for intensive mixing and uniform dispersion.

- Conical Screw Mixers: Handle delicate or segregative powders.

- Fluidized Zone Mixers: Provide fast, weightless blending with minimal shear.

- Integrated choppers can be added to break down clumps and improve uniformity.

3. Vacuum Environment

- A vacuum pump removes air and moisture to reduce internal pressure.

- Lower pressure allows drying at reduced temperatures—ideal for heat-sensitive materials.

4. Heating and Cooling

- The mixer’s jacketed design allows steam, oil, or water to regulate internal temperature:

- Heat speeds up evaporation and drying.

- Cooling maintains stability for sensitive products.

5. Drying Process

- Vacuum speeds up evaporation and enables low-temperature drying.

- Optional condensation recovery systems can reclaim solvents and improve efficiency.

6. Discharge

- Product is discharged via a bottom outlet for easy removal.

- For sticky or viscous materials, optional tilt discharge or screw systems are available.

Advantages of the Working Principle

-

- Faster Processing: Vacuum dramatically shortens drying cycles.

- Energy Efficiency: Lower temps reduce energy usage.

- Superior Quality: Controlled mixing minimizes heat damage and segregation.

- Application Flexibility: Handles powders, pastes, granules, and more.

- Hygienic Design: Closed system supports GMP and food safety standards.

This innovative mixing and drying method makes PerMix Vacuum Mixers/Dryers the go-to choice for manufacturers seeking consistent quality, rapid processing, and reduced energy consumption—all in a single compact system.

Special Features and Construction of PerMix Vacuum Mixers/Dryers for Specialized Applications

Special Features and Construction of PerMix Vacuum Mixers/Dryers for Specialized Applications

PerMix Vacuum Mixers/Dryers are engineered for exceptional performance across a wide range of materials and industries. Designed with robust construction and advanced functionality, they deliver reliable results for even the most demanding applications.

Special Features

1. Integrated Vacuum System

- High-efficiency vacuum pumps ensure low-temperature drying ideal for sensitive materials.

- Creates a contamination-free environment, critical for food, pharmaceutical, and chemical applications.

2. Precision Heating & Cooling Jackets

- Multi-zone jacket systems deliver accurate temperature control using steam, water, or thermal oil.

- Supports high-temperature drying up to 350°C and offers cryogenic options for ultra-low processing needs.

3. Choppers for De-Agglomeration

- High-speed choppers ensure consistent product texture by breaking down agglomerates.

- Inlet ports allow liquid additives during mixing and drying, ensuring optimal incorporation.

4. Condensate Recovery System

- Efficiently recaptures solvents and moisture for reuse, reducing waste and enhancing sustainability.

5. Vacuum Loading and Discharge Systems

- Vacuum-assisted loading streamlines operations by eliminating the need for external equipment.

- Flexible discharge options—tilting or screw-type—simplify unloading of sticky or viscous materials.

6. PLC/HMI Controls

- Advanced controls enable real-time monitoring of vacuum, temperature, and mixing speeds.

- Automated recipe storage ensures consistent results across batches.

7. Explosion-Proof Configurations

- Specialized setups are available for safe processing of flammable or volatile materials.

- Compliant with safety standards required in industries such as chemicals and battery production.

Specialized Construction for Unique Applications

1. Materials of Construction

- 304 and 316 stainless steel for food and pharmaceutical safety.

- Hardox for abrasive materials.

- Hastelloy and Titanium for highly corrosive processes.

- Carbon Steel for economical use in less demanding conditions.

2. Sanitary Design

- Smooth internal finishes minimize residue build-up and simplify cleaning.

- Welded designs meet stringent FDA and GMP hygiene standards.

- Optional CIP systems support wet or waterless cleaning cycles.

3. Special Geometries

- Flat-bottom options ensure complete discharge of sticky materials.

- Conical designs for delicate or easily segregated powders.

- Multi-shaft setups allow hybrid mixing for complex formulations.

4. Enhanced Sealing Options

- Air purge seals prevent product ingress in sanitary environments.

- Gas purge options enable inert conditions for reactive ingredients.

5. Scalable Solutions

- From lab-scale units to full-size production systems, we support smooth scale-up.

6. Custom Agitation Systems

- Options include ribbon, paddle, plow, and screw mixers.

- Additional components like intensifier bars optimize specialty processing.

Applications Requiring Special Features & Construction

- Pharmaceuticals

- Vacuum drying of actives and formulations under sterile conditions.

- Food & Nutraceuticals

- Sanitary mixing and drying of protein blends, spices, and supplements.

- Chemicals

- Safe handling of corrosive or abrasive powders with integrated solvent recovery.

- Nanotechnology

- Advanced control and construction for sensitive and high-purity processes.

- Battery Production

- Explosion-proof vacuum drying systems for electrodes and compounds.

Driven by engineering precision and industry innovation, PerMix Vacuum Mixers/Dryers are trusted worldwide for specialized mixing and drying solutions. Contact PerMix to learn more.

Advantages

-

Advantages of PerMix Vacuum Mixers/Dryers

PerMix Vacuum Mixers/Dryers offer an advanced solution for industries seeking high-performance powder mixing and drying capabilities. Engineered for precision and adaptability, these machines combine state-of-the-art vacuum technology with robust construction to deliver exceptional results in pharmaceutical, food, chemical, and nutraceutical applications.

1. Exceptional Efficiency

- Rapid Drying: Vacuum-assisted drying significantly reduces processing times by lowering the boiling point of moisture or solvents.

- Energy Smart: Efficient thermal transfer at reduced temperatures helps cut energy consumption.

- Built-In Temperature Control: Integrated heating and cooling jackets ensure stable processing conditions throughout the cycle.

2. Consistent Product Quality

- Protects Heat-Sensitive Materials: Low-temperature vacuum drying preserves the integrity of delicate ingredients.

- Contamination-Free: Airtight chambers prevent oxidation and maintain purity in critical applications.

- Even Mixing: Advanced agitation systems guarantee uniform distribution, even with sticky or abrasive components.

3. Versatile and Customizable

- Dual-Function Capability: Combines industrial mixing and drying in one compact unit.

- Application-Focused Mixing: Choose from plow, paddle, ribbon, or screw mixers to suit your process needs.

- Adaptable to Materials: Handles everything from light powders to viscous pastes with ease.

4. Advanced Process Control

- Precision Monitoring: PLC/HMI interfaces allow real-time adjustments and full control of all process parameters.

- Recipe Storage: Save configurations for consistent repeatable batches.

- Solvent Recovery: Optional systems recapture valuable solvents for reuse.

5. Hygienic and Safe Design

- Sanitary Construction: Built with GMP-compliant materials and finishes ideal for food and pharma environments.

- Easy-to-Clean Systems: Optional CIP and waterless CIP technologies streamline maintenance.

- Explosion-Proof Options: Available for safe processing of volatile or flammable materials.

6. Built for Longevity

- Rugged Materials: Options include stainless steel 304/316, Hastelloy, Hardox, and titanium for tough conditions.

- Custom Builds: Configurable for lab-scale R&D or full-scale industrial production.

7. Cost-Effective Innovation

- Lower Operating Costs: Energy savings and faster cycle times lead to long-term cost reduction.

- Efficient ROI: Multitasking capability delivers greater value over time.

- Affordable Engineering: Designed for high performance without excessive investment.

8. Application-Ready Performance

- Pharmaceuticals: Ideal for precise drying and blending of active pharmaceutical ingredients (APIs).

- Food Processing: Efficiently processes flavorings, nutrition powders, and shelf-stable ingredients.

- Chemicals: Built to withstand abrasive and corrosive compounds.

- Nano & Specialty Materials: Delivers exacting control for high-tech industries.

PerMix Vacuum Mixers/Dryers are trusted globally for their engineering quality, process adaptability, and high return on investment. If you’re looking to elevate your production capabilities, contact PerMix and discover what makes us a leader in industrial mixing and drying technology.

Horizontal Vacuum Mixer & Dryers

Advantages of PerMix Vacuum Mixers/Dryers

PerMix Vacuum Mixers/Dryers are engineered to deliver exceptional results in mixing and drying applications across a wide range of industries. Combining advanced vacuum technology with precision engineering, these systems provide a high-performance solution for companies looking to streamline production, improve product quality, and reduce processing times.

1. Exceptional Efficiency

- Vacuum technology accelerates drying by lowering the boiling point of moisture.

- Reduces both processing time and energy consumption.

- Integrated heating and cooling jackets ensure precise temperature control.

2. Consistent Product Quality

- Operates at lower temperatures to protect sensitive materials.

- Sealed design prevents oxidation and contamination.

- Advanced agitators handle everything from powders to sticky pastes.

3. Versatility and Customization

- Handles free-flowing powders and viscous pastes.

- Combines mixing and drying in a compact footprint.

- Customizable agitator options: plow, ribbon, paddle, or screw.

4. Advanced Process Control

- Equipped with PLC/HMI interface for real-time adjustments.

- Save and recall recipes for consistent batch production.

- Optional solvent recovery system minimizes waste and saves resources.

5. Hygienic and Safe Design

- Constructed from 316 stainless steel for sanitary operations.

- Polished surfaces minimize product buildup and ease cleaning.

- CIP and waterless CIP options available.

- Explosion-proof designs for volatile environments.

6. Durable Construction

- Available in materials like Hastelloy, Hardox, or carbon steel.

- Designed to withstand heavy industrial usage.

- Engineered for longevity and reliable performance.

7. Cost-Effective Operation

- Integrates multiple functions into one efficient system.

- Shorter cycle times reduce labor and energy costs.

- Faster ROI through performance-driven savings.

8. Application Versatility

- Pharmaceuticals: Precision mixing and vacuum drying of APIs and excipients.

- Food & Beverage: Creates stable, flavorful powders while retaining nutrients.

- Chemicals: Handles abrasive, corrosive, or complex materials efficiently.

- Nanotechnology: Supports ultra-precise blending under controlled conditions.

PerMix Vacuum Mixers/Dryers are trusted by manufacturers worldwide for their reliability, flexibility, and performance. Whether you’re optimizing current processes or launching a new product line, PerMix delivers results that drive success.

Vertical Vacuum Mixers & Dryers

Types of PerMix Vertical Vacuum Mixers/Dryers

PerMix vertical vacuum mixers/dryers are engineered to deliver exceptional performance in a compact footprint. Designed for efficient powder mixing and drying, these space-saving units are ideal for processing powders, granules, and pastes—especially when working with heat-sensitive or delicate materials. Their upright construction promotes excellent heat transfer and effective vacuum drying, making them a smart choice for high-precision industrial applications.

1. Vertical Ribbon Vacuum Mixers/Dryers

- Overview: A flexible solution for gentle blending and efficient drying in vacuum conditions.

- Mixing Mechanism: Ribbon agitator lifts material along the walls and folds it back down the center.

- Ideal For:

- Food & Beverage: Protein powders, dry seasoning blends, functional ingredients

- Pharmaceuticals: Light and sensitive powder formulations

- Key Benefits:

- Soft mixing action ideal for fragile components

- Reduced energy usage during drying

- Compact design perfect for limited floor space

2. Vertical Paddle Vacuum Mixers/Dryers

- Overview: Built to handle a wide range of products, especially fragile or thermally sensitive materials.

- Mixing Mechanism: Counter-rotating paddles generate dynamic flow with low shear force.

- Ideal For:

- Pharmaceuticals: APIs, powdered medications

- Nutraceuticals: Herbal supplements, vitamin powders

- Key Benefits:

- Effective drying under vacuum conditions

- Minimal product damage during mixing

- Optional choppers for lump-free consistency

3. Conical Screw Vacuum Mixers/Dryers

- Overview: Designed for gentle mixing and drying of segregative, fragile, or paste-like materials.

- Mixing Mechanism: Rotating screw conveys material upward while gravity enables even downward flow.

- Ideal For:

- Pharmaceuticals: Fine powders and fragile granulates

- Food: Delicate formulations requiring low shear

- Chemicals: Heat-sensitive or brittle materials

- Key Benefits:

- High drying efficiency with low energy input

- Prevents product degradation

- Great for facilities with space constraints

4. Vertical Vacuum Paddle Mixers/Dryers with Flat Bottom

- Overview: Ideal for sticky, viscous materials or processes that demand complete discharge.

- Mixing Mechanism: Dual paddles deliver thorough mixing, with optional choppers to break down clumps.

- Ideal For:

- Pharmaceuticals: Powder capsule blends and vegetable-based powders

- Food: High-viscosity or cohesive mixtures

- Key Benefits:

- Flat-bottom chamber promotes easy product discharge

- Integrated spray nozzles for liquid additives

- Hygienic design with easy-clean components

Specialized Features of PerMix Vertical Mixers/Dryers

- Vacuum Technology: Enables low-temp drying for quality preservation and reduced oxidation.

- Integrated Heating & Cooling: Multi-zone jackets support precise thermal control with steam, thermal oil, or water.

- Tailored Construction Materials: Options include 304/316 stainless steel, Hastelloy, titanium, Hardox, or carbon steel.

- Condensate Recovery Systems: Capture evaporated solvents for reuse.

- Compact Footprint: Vertical design saves space and suits lab-scale or small facility production.

- CIP Options: Choose traditional or waterless Clean-In-Place systems.

- Explosion-Proof Designs: ATEX-compliant configurations available for hazardous environments.

Applications of PerMix Vertical Vacuum Mixers/Dryers

- Pharmaceuticals: Drying and mixing APIs, excipients, and granules

- Food & Beverage: Blending powdered ingredients and functional additives

- Nutraceuticals: Consistent production of herbal blends and dietary powders

- Chemicals: Processing corrosive, abrasive, or heat-sensitive compounds

- Nanotechnology: Handling advanced materials with exact vacuum and temperature controls

Why Choose PerMix Vertical Vacuum Mixers/Dryers?

- Intelligent design that saves space while maximizing performance

- Gentle, uniform mixing and efficient vacuum drying for challenging materials

- Scalable and customizable solutions to match your specific application

- Backed by decades of engineering expertise, innovation, and competitive pricing

Contact PerMix today to find the vertical vacuum mixing solution that meets your production goals and delivers real results.

Tumble Vacuum Mixers & Dryers

PerMix Tumble Vacuum Mixers/Dryers

PerMix tumble vacuum mixers/dryers are precision-engineered to provide gentle yet highly effective blending and drying of powders, granules, and temperature-sensitive materials. By combining slow rotational motion with vacuum technology, these machines ensure excellent homogeneity while preserving product integrity—making them an ideal choice for industries that require careful material handling and consistent results.

Types of PerMix Tumble Vacuum Mixers/Dryers

1. Double Cone Vacuum Mixers/Dryers

- Overview: Built with a double-cone design for low-shear mixing and uniform vacuum drying in a single unit.

- Mixing Motion: Rotational motion allows natural material flow, ensuring even blending without mechanical agitation.

- Common Uses:

- Pharmaceuticals: Drying and blending APIs and powder-based formulations

- Food & Beverage: Spice mixes, protein powders, nutritional blends

- Chemicals: Heat-sensitive or fine-particle compounds

- Key Benefits:

- Gentle motion protects particle shape and structure

- Vacuum system accelerates moisture removal

- Optional intensifier bars for enhanced homogeneity

2. V-Blender Vacuum Mixers/Dryers

- Overview: Classic V-blender design trusted for uniform blending in low-shear environments.

- Mixing Motion: V-shaped vessel rotation cascades powders evenly. Vacuum integration shortens drying time.

- Common Uses:

- Pharmaceuticals: Capsule and tablet powder blends

- Nutraceuticals: Protein mixes and herbal supplements

- Specialty Chemicals: Consistent low-impact powder mixing

- Key Benefits:

- Gentle handling for fragile or segregative materials

- Sanitary, easy-to-clean design

- Compact and space-saving configuration

3. 3D Tumble Vacuum Mixers/Dryers

- Overview: Designed for complex materials with three-axis motion for uniform blending and drying.

- Mixing Motion: Multi-directional movement promotes deep particle distribution and uniform flow.

- Common Uses:

- Pharmaceuticals: Sensitive formulation blending

- Chemicals: Varying density and flow powder mixing

- Cosmetics: Pigment and fine powder homogenizing

- Key Benefits:

- Excellent uniformity with difficult materials

- Ideal for small-batch, high-precision applications

- Energy-efficient and space-saving

Standout Features of PerMix Tumble Vacuum Mixers/Dryers

- Advanced Vacuum Technology: Speeds up drying at low temperatures, minimizing oxidation and maintaining product integrity.

- Precision Heating & Cooling: Jacketed systems allow exact thermal control with steam, water, or thermal oil. Cryogenic options available.

- Sanitary Construction: Built with 304/316 stainless steel, polished interiors, and GMP-compliant designs.

- Custom Intensifier Bars: Break up agglomerates to improve blend quality and consistency.

- Efficient Discharge Design: Gravity-based systems with optional valves for viscous or tough products.

- Compact and Scalable: Suitable for limited space, from lab to large-scale production.

- Explosion-Proof Options: Available for hazardous or ATEX-regulated environments.

Core Advantages of PerMix Tumble Vacuum Mixers/Dryers

- Low-Shear, Gentle Mixing: Protects fragile particles and sensitive ingredients.

- Highly Efficient Vacuum Drying: Removes moisture quickly while preserving quality.

- Consistent and Homogeneous Blending: Ensures batch-to-batch uniformity, even with varied material properties.

- Compact Footprint: Saves floor space without compromising performance.

- Flexible Customization: Tailored materials, sizes, and features for industry-specific needs.

Applications Across Industries

- Pharmaceuticals: Blending APIs and drying powder formulations with high precision

- Food & Beverage: Mixing spice blends, nutritional powders, and flavoring agents

- Nutraceuticals: Producing consistent herbal and protein supplement blends

- Chemicals: Handling fine, abrasive, or volatile compounds

- Cosmetics: Homogenizing pigment powders and fragrance bases

Why Choose PerMix Tumble Vacuum Mixers/Dryers?

- Advanced tumble vacuum technology backed by decades of engineering expertise

- Exceptional performance, durability, and easy operation

- Ideal for scale-up or optimization of existing processes

- Combines gentle mixing, efficient drying, and compact design

Get in touch today to discover how our tumble vacuum mixers and dryers can elevate your production.

4-in-1 Vacuum Mixers & Dryers

Introducing the PerMix 4-in-1 Hybrid Vacuum Mixer/Dryer

The PerMix 4-in-1 Hybrid Vacuum Mixer/Dryer redefines versatility in industrial mixing and drying. By merging four powerful mixing technologies—ribbon, plow, paddle, and fluidized zone—into a single, vacuum-integrated system, it offers unmatched flexibility and performance across a wide range of industries. Designed for manufacturers who demand efficiency and precision, this all-in-one solution streamlines complex processes and minimizes equipment investment.

What Is the PerMix 4-in-1 Hybrid Vacuum Mixer/Dryer?

- Ribbon Mixing: Gentle blending of free-flowing powders and light granulates.

- Plow Mixing: High-intensity action for cohesive or sticky materials.

- Paddle Mixing: Low-shear, controlled mixing for fragile or heat-sensitive products.

- Fluidized Zone Mixing: Ultra-fast, “weightless” blending for complex, multi-phase materials.

The PerMix 4-in-1 Hybrid seamlessly integrates multiple capabilities into one compact machine:

- Mixing: Uniform blending of powders, granules, or pastes.

- Granulating: Built-in high-shear mixing for precise granule formation.

- Vacuum Drying: Low-temperature moisture removal that protects delicate ingredients.

- Cooling: Post-drying stabilization to maintain product quality.

Key Features of the Hybrid Vacuum Mixer/Dryer

1. Multi-Mixing Technology

- Interchangeable tools: ribbon, plow, paddle, or fluidized zone.

- Adaptable to diverse material types and process goals.

2. Vacuum-Assisted Processing

- Faster drying at lower temperatures.

- Prevents oxidation and maintains formulation purity.

3. Precision Heating & Cooling

- Multi-zone jacketed system with steam, thermal oil, or water.

- Handles high-temperature (up to 350°C) or cryogenic conditions.

4. Integrated Granulation

- Optional high-speed choppers for on-the-fly granulation.

- Improves consistency and control over particle size.

5. Smart Automation & Control

- PLC/HMI interface for full process control.

- Recipe memory ensures repeatable quality across batches.

6. Hygienic, Durable Construction

- Material choices: 304/316 stainless, Hastelloy, Hardox, titanium.

- GMP- and FDA-compliant designs with optional polished surfaces.

7. Space-Efficient Design

- Consolidates four machines into one.

- Reduces floor space needs and simplifies operations.

Benefits of the PerMix 4-in-1 Hybrid System

1. Versatile Performance

- One system for many product types and processing needs.

2. Complete Process Integration

- Mix, granulate, dry, and cool in one cycle.

- Minimizes product transfer and machine investment.

3. Energy and Time Efficiency

- Vacuum reduces drying time and energy use.

- Precision temperature control boosts reliability.

4. Consistent Product Quality

- Uniform blending and moisture control.

- Handles powders, pastes, and sensitive ingredients.

5. Fully Customizable

- Configurable for pilot-scale or large production.

- Adaptable to your material and industry.

Industry Applications

- Pharmaceuticals: Granulating APIs, drying excipients, stabilizing blends.

- Food & Beverage: Protein mixes, instant powders, flavor blends.

- Nutraceuticals: Herbal supplements, vitamins, and functional foods.

- Chemicals: Mixing and drying specialty compounds and pigments.

- Cosmetics: Skincare powders, makeup bases, and fragrances.

- Nanotechnology: Advanced material processing under tight controls.

Why Choose PerMix’s 4-in-1 Hybrid Vacuum Mixer/Dryer?

- Compact, multi-function system tailored for modern production lines.

- Reduces costs, floor space, and handling time.

- Supports both scale-up and optimization strategies.

- Delivers reliable, high-quality results batch after batch.

Contact PerMix today to discover how our Hybrid Vacuum Mixer/Dryer can elevate your mixing and drying operations.

Need Help Selecting Your Equipment?

Talk to our product expert today

PerMix is here to listen to your needs and provide sustainable solutions. Contact us to discover more.