Industrial Mixers

PerMix Powder Induction Mixer

Why Choose PerMix Powder Induction Mixer

The PerMix PT-C Series Powder Induction Mixer is a line of equipment specifically designed to efficiently and rapidly mix powders into liquids.

Powder Induction Mixer Introduction

🔹 Versatile Functions of the PerMix PT-C Powder Induction Mixer

By selecting from a range of specialized rotating elements, the PerMix PT-C Powder Induction Mixer is capable of delivering multiple functions to meet diverse processing needs:

- ✅ High-volume powder induction

- ✅ Dispersion of difficult-to-wet powders

- ✅ Handling of fine, dusty powders

- ✅ Homogenization

- ✅ Emulsification

🔹 Available Models for Different Applications

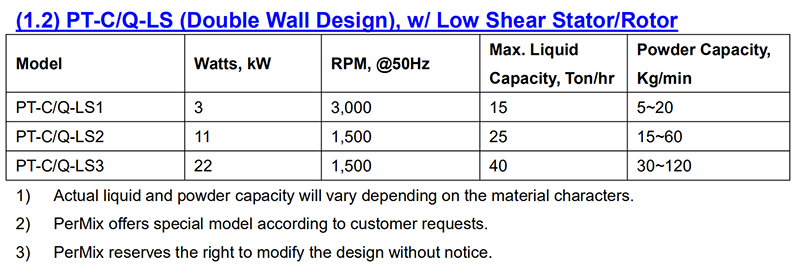

PerMix offers four models of Powder Induction Mixers to meet a broad range of industry requirements:

- ✅ PT-C/Q – Double Wall Design

- ✅ PT-C/Y – Special Stator-Rotor Configuration

- ✅ PT-C/F – Dual Pump Design

- ✅ PCH – Shear Pump

🔹 Wide Range of Industry Applications

With numerous customizable features and high-performance capabilities, PerMix PT-C Powder Induction Mixers are widely used across various industries, including:

- ✅ Food & Beverage

- ✅ Dairy & Personal Care

- ✅ Pharmaceutical

- ✅ Chemical

These mixers are ideal for processing nearly all types of powder-based ingredients with efficiency, precision, and consistency.

How It Works

🔹 Types of PerMix Powder Induction Mixers

The four types of PerMix Powder Induction Mixers share a similar working principle but feature distinct structural differences to suit specific processing needs:

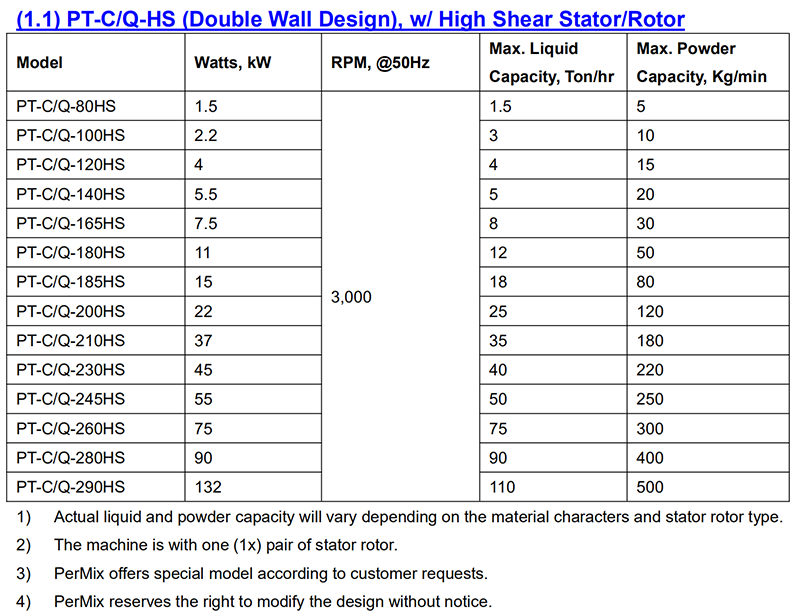

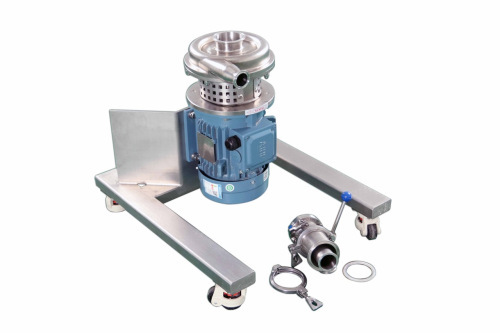

🔹 (1) PT-C/Q – Double Wall Design Powder Induction Mixer

The PT-C/Q Powder Induction Mixer, also known as a Tri-Blender, is the most common model. It consists of two core components: a casing pipe and a stator-rotor system. The casing pipe is built vertically and coaxially into the rotor-stator inlet, creating a double-wall design that prevents premature contact between powder and liquid—eliminating lumps before both enter the mixing chamber.

As the rotor spins at high speed, a water ring forms inside the chamber. This generates a vacuum at the center, drawing powder from the hopper above. A valve at the hopper base regulates the powder’s flow rate. Once inside, the powder is instantly wetted and dispersed by turbulence, then subjected to high shear mixing as it passes through the precise rotor-stator clearance.

Various stator-rotor combinations are available to match different processing needs—from high shear homogenization to gentle wetting. In some cases, a standard centrifugal pump impeller is used instead of a rotor-stator pair for higher flow rates and powder induction performance.

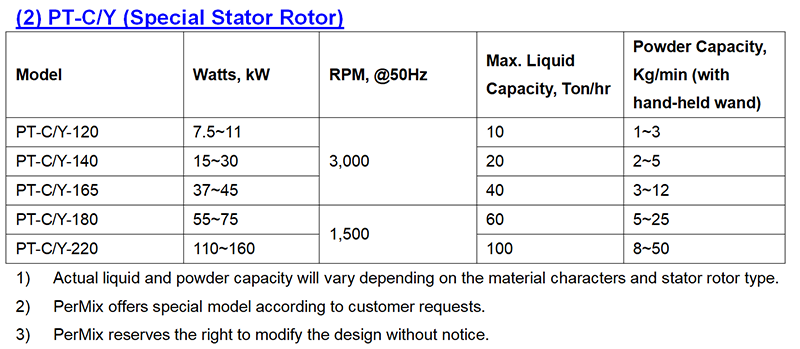

🔹 (2) PT-C/Y – Special Stator-Rotor Powder Induction Mixer

The PT-C/Y series features a specially designed rotor-stator system that works similarly to a water ring pump, creating a relatively high vacuum. This allows the mixer to draw powder through a hand-held wand from bags or containers on the floor. Alternatively, powder can be gravity-fed from a vertical hopper at a higher suction rate. This model is ideal for ergonomic, flexible operations in a variety of processing environments.

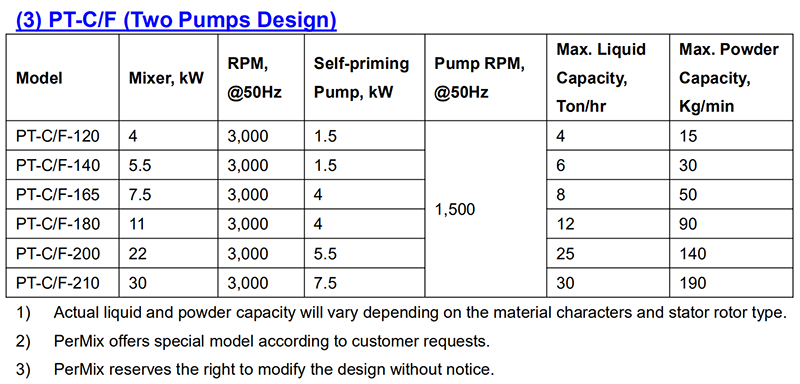

🔹 (3) PT-C/F – Dual Pump Design Powder Induction Mixer

The PT-C/F Powder Induction Mixer combines a self-priming pump with an inline homogenizing mixer. The self-priming pump draws liquid from an external source and passes it through a venturi pipe located beneath a powder hopper. This setup creates vacuum pressure, pulling powder from above into the mixing stream.

The powder-liquid mixture first passes through the self-priming pump, then enters the inline high shear mixer for further homogenization and dispersion—ideal for continuous powder-liquid processing.

🔹 (4) PCH – Shear Pump for Powder Induction

The PCH Shear Pump can be adapted into a powder induction system by attaching a hopper at the liquid inlet. This setup works especially well for dry, free-flowing powders such as milk powder or flour. Thanks to its compact, hygienic design and full stainless steel construction, the PCH model is widely used in the food, dairy, and pharmaceutical industries.

Despite its simplicity, the PCH Shear Pump delivers strong suction performance and consistent mixing results—making it a reliable and efficient solution for various powder-liquid blending tasks.

Applications

🔹 Typical Applications of PerMix Powder Induction Mixers

- Preparation of syrup, sorbitol, glucose, lactose, and similar sweeteners

- Reconstitution of powdered milk, whey, protein, and nutritional supplements

- Dissolution of hydrocolloids like CMC and xanthan gum

- Preparation of flour and starch slurries for food processing

- Mixing and preparation of brines for meat and seafood curing

- Pre-mixing of yogurt bases and other milk-based desserts

- Suspension of bentonite and titanium dioxide in pigment formulations

- Formulation of liquid pesticides, fertilizers, and agricultural solutions

Options

🔹 Optional Features for the PerMix PT-C Powder Liquid Mixer

- Hand-held powder hose assembly for flexible feeding

- Variable speed motor with integrated frequency converter

- Multi-row, multi-stage stator and rotor configurations

- Metal parts available in SS316L or other custom materials

- Gasket sealing options including FPM, FFPM, and more

- Hopper angle options such as 50°, 60°, etc.

- Hopper enhancements like vibrator or air sweeper systems

- Choice of single or double mechanical seals for process-specific sealing

Automating Hand Sanitizer Production Using PerMix High Shear Powder Induction Mixers

🔹 Automated Hand Sanitizer Production with PerMix High Shear Mixers

Automating hand sanitizer manufacturing using PerMix High Shear Mixers enables streamlined production with consistent quality, improved hygiene, and efficient throughput. Below is a step-by-step guide to setting up an optimized system:

🔹 1. Equipment Selection

- ✅ Choose a PerMix High Shear Mixer—inline or batch type—for precise liquid mixing.

- ✅ Ensure the mixer is made of 316L stainless steel for sanitary, corrosion-resistant operation.

🔹 2. Integration of Raw Material Handling

- ✅ Use an automated dosing system for alcohol, glycerin, and water.

- ✅ Install metered pumps for accurate liquid dosing.

- ✅ Add dry ingredients via vacuum conveyor or hopper feeding system.

- ✅ Include sanitary storage tanks with level sensors for pre-mixing staging.

🔹 3. Mixing Process Automation

- ✅ Equip the mixer with a PLC and HMI for full recipe and process control.

- ✅ Automate loading, mixing time, speed, and temperature control (if applicable).

- ✅ Achieve homogenization through the rotor-stator system of the high shear mixer.

🔹 4. Optional Heating & Cooling

- ✅ Use a jacketed tank to manage temperature for gel-based sanitizers.

🔹 5. Quality Assurance

- ✅ Install inline sensors to measure pH, viscosity, or alcohol content.

- ✅ Use IoT-enabled monitoring for real-time quality control.

🔹 6. Discharge & Filling

- ✅ Connect the mixer to a pump-assisted discharge system feeding directly to bottling lines.

- ✅ Use automated fillers, cappers, and labelers for seamless packaging.

🔹 7. Cleaning & Sanitization

- ✅ Equip with a CIP (Clean-in-Place) system for post-batch cleaning.

- ✅ Options include water-only, air-only, or combination cycles.

🔹 8. Data Logging & Reporting

- ✅ Log batch data including ingredient volumes, mixing times, and quality metrics.

- ✅ Use data for traceability, regulatory compliance, and process optimization.

🔹 9. Scale-Up for Large Production

- ✅ Integrate multiple mixers with a centralized control system for parallel batch production.

🔹 10. Compliance & Safety

- ✅ Ensure the system follows GMP and relevant regulatory standards.

- ✅ Use explosion-proof mixers when handling alcohol-based formulations.

This automated mixing system for hand sanitizer production delivers consistent output, minimizes manual handling, and meets hygiene and regulatory requirements. Let us know if you’d like a custom equipment layout or process diagram tailored to your facility.

Need Help Selecting Your Equipment?

Talk to our product expert today

PerMix is here to listen to your needs and provide sustainable solutions. Contact us to discover more.