Industrial Mixers

PerMix Emulsifier

Why Choose PerMix Emulsifier

PerMix Inline Homogenizer Mixer is a high shear mixer designed for continuous or inline processing. In this setup, the mixer is mounted outside the tank for streamlined integration and efficient operation.

Introduction

🔹 PerMix Inline Homogenizer Mixers: Efficient, High Shear Mixing on the Move

The PerMix Inline Homogenizer Mixer is a powerful high shear mixer engineered for continuous, inline processing. Designed for external installation, it easily integrates into existing production lines through standard inlet and outlet connections, making it ideal for retrofitting without major system changes.

When working with low-viscosity liquids, this inline homogenizer can often function without the need for an additional pump—earning it the nickname High Shear Pump. It offers exceptional versatility, capable of processing materials in a single pass or through multiple recirculation cycles to achieve enhanced results.

- ✅ Seamless integration into existing mixing equipment setups

- ✅ Eliminates need for extra pumping in low-viscosity applications

- ✅ Ideal for continuous mixing and homogenizing operations

- ✅ Reduces process times by up to 90%

Unlike a batch high shear mixer, the PerMix inline model performs mixing within a dedicated high-efficiency chamber. This ensures optimal energy transfer to the product, leading to faster emulsification and improved consistency—making it an excellent choice for applications involving vacuum emulsifiers, powder induction systems, and mixer polymer solutions.

Working Principles

🔹 How the PerMix Inline Homogenizer Mixer Works

The PerMix Inline Homogenizer Mixer operates using high-speed rotor-stator technology to deliver efficient and consistent results in liquid-solid processing. Here’s how the mixing process unfolds:

- ✅ Step 1: High-Speed Rotor Activation

Once the motor activates, the rotor spins at extremely high speeds—often several thousand RPM. This motion creates a powerful suction at the rotor’s center, drawing both solids and liquids into the mixing chamber through the inlet. - ✅ Step 2: Centrifugal Acceleration & Precision Milling

The incoming materials are pushed outward by centrifugal force. They pass through the tight clearance between the rotor and stator, where they undergo intense squeezing, shear, and impact milling. The pressure buildup enhances particle interaction, aiding in efficient size reduction. - ✅ Step 3: High-Velocity Shear & Particle Dispersion

As the materials exit the stator at high velocity, they encounter another intense shear force. The sudden drop in pressure causes particles to burst into even finer pieces, promoting superior emulsification and dispersion—ideal for applications in powder induction mixers and vacuum emulsifiers. - ✅ Step 4: Continuous Circulation or Single-Pass Flow

Fresh materials are continually pulled into the stator-rotor zone, enabling a seamless continuous flow or single-pass operation. This ensures consistent product quality, especially in high-demand industrial mixing environments.

Mixer Stator/Rotor System

🔹 Customizable Stator & Rotor Systems by PerMix

At PerMix, versatility meets precision with two advanced stator and rotor designs: the K-type and V-type. Each system includes several sub-types to meet diverse application needs, allowing customers to select the most effective configuration for processing their specific liquid-solid mixtures using inline mixers or high shear mixers.

🔹 Multi-Stage & Multi-Row Rotor/Stator Assemblies

- ✅ Multi-Row Configuration

Both stators and rotors can feature multiple rows of functional surfaces—such as “teeth” (K-type), “blades” (V-type rotor), or “screens” (V-type stator)—to enhance shear intensity and mixing efficiency. - ✅ Multi-Stage Mixing Options

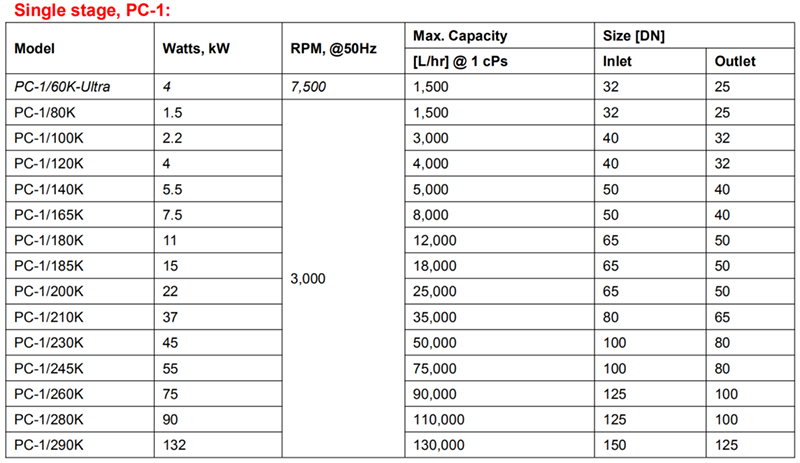

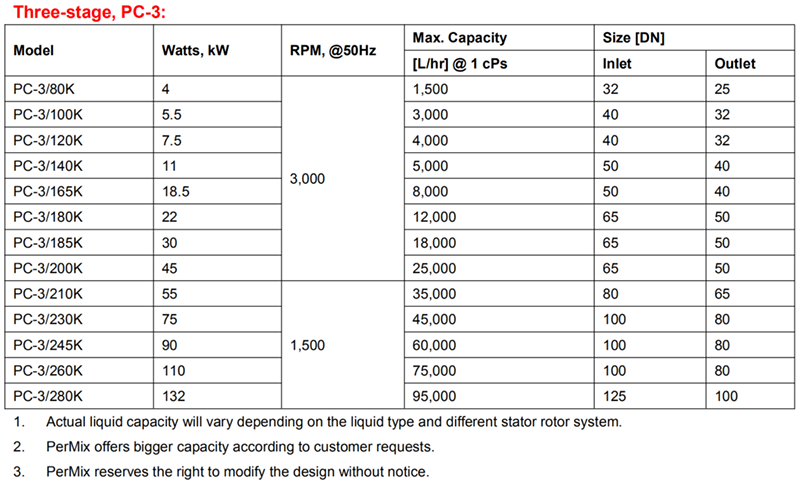

PerMix offers the PC1 series as a single-stage inline mixer and the PC3 series as a multi-stage model. The PC3 inline mixer integrates three sets of stator and rotor assemblies—coarse, intermediate, and fine—for superior dispersion and emulsification in single-pass processing. - ✅ Enhanced Shearing Performance

The triple-stage system in the PC3 significantly boosts shearing power, making it ideal for difficult-to-disperse materials or processes that demand a high degree of homogenization. This reduces processing time while improving end-product consistency. - ✅ Customizable Tooth Profiles

Each stator/rotor pair can be configured with coarse, medium, or fine teeth, in either single-row or multi-row layouts, to precisely match your desired shear intensity.

🔹 Ultra-High Speed Inline Mixers

PerMix also engineers ultra-high speed inline mixers to meet demanding industrial mixing needs. These mixers feature tip speeds of approximately 40 m/s and utilize a belt-driven system to achieve rotor speeds up to 12,000 RPM, as seen in the PC-1/60 pilot-size model. This performance is perfect for applications requiring fast and fine particle dispersion or powder induction system integration.

- ✅ Belt-driven rotor design for maximum rotational speed

- ✅ Tip speeds up to 40 meters per second

- ✅ Ideal for high-speed emulsification and homogenization tasks

Emulsifiers & Inline Homogenizer Thermosiphon For Double Mechanical Seals

🔹 PerMix Thermosiphon System: Protecting Seal Integrity with Reliable Cooling

The PerMix Thermosiphon system is designed to store and cool buffer liquid for double mechanical seals, ensuring long-lasting performance and protection in closed-loop industrial operations. By compensating for buffer fluid loss, the thermosiphon prevents dry running of the seals—significantly extending their service life and reliability.

Operating on the principle of the Thermosiphon Effect or via forced circulation, the system enables the heated buffer liquid to flow from the mechanical seals to the thermosiphon, where it is cooled and recirculated. This continuous cooling cycle is critical for demanding applications, such as those involving vacuum mixers, high shear mixers, or other high-performance industrial mixing equipment.

- ✅ Closed-circuit cooling for double mechanical seals

- ✅ Prevents seal failure due to overheating or dry running

- ✅ Supports continuous and safe operation of industrial mixers

Crafted from durable SS304 or SS316L stainless steel, the PerMix thermosiphon tank includes essential features such as a pressure gauge, sight glass, and fully integrated nozzles for easy installation. It is available with or without a built-in cooling coil, allowing buffer liquid to be cooled using external water sources as needed.

- ✅ Stainless steel construction for hygienic and corrosive environments

- ✅ Optional cooling coil for enhanced thermal control

- ✅ Complete with installation brackets and fittings

Applications

- ✅ Food & Beverage

Reconstituted milk, salad dressing, mayonnaise, ice cream, cheese, yogurt, fruit juice - ✅ Pharmaceutical & Nutraceutical

Drug synthesis, vaccines, fat emulsions, injectable suspensions, veterinary medicine, cell extraction - ✅ Cosmetics & Personal Care

Detergents, body gel, shampoo, creams, lotions, toothpaste, soap - ✅ Chemicals & Oil Industry

Synthetic rubber, resin, bitumen, silicone oil, dyes, pigments, coatings, inks, nanomaterials

Automation of Wet Wipes Manufacturing Using Inline Mixers

🔹 How to Manufacture Wet Wipes Using Only an Inline Mixer

With the right equipment and setup, it’s entirely possible to produce wet wipes using a high shear inline mixer as the core of a fully automated, continuous production system. This approach enhances consistency, reduces processing time, and supports scalable manufacturing.

🔹 1. Inline Mixer Configuration

- ✅ Use a PerMix inline mixer designed for high shear mixing, emulsification, and homogenization

- ✅ Select a model with adjustable shear intensity for flexibility across different wet wipe formulations

- ✅ Ensure continuous flow operation for uninterrupted processing

🔹 2. Automated Ingredient Dosing System

A. Liquid Ingredients

- ✅ Metering Pumps: Use peristaltic or diaphragm pumps to deliver precise liquid volumes to the mixer’s inlet

- ✅ Flow Meters: Monitor real-time dosing rates for accuracy

- ✅ Multi-Channel Manifolds: Combine several liquid streams into one controlled input

B. Powder Ingredients (If Required)

- ✅ Powder Induction System: Equip the mixer with a vacuum-assisted powder induction system for seamless dry ingredient incorporation

- ✅ Volumetric or Gravimetric Feeders: Synchronize feeders with the mixer’s flow rate for accurate powder dosing

🔹 3. Ingredient Introduction Methods

- ✅ Direct Injection Ports: Install multiple ports on the mixer with independent dosing control

- ✅ Pre-Mixing Tanks: Optional tanks for ingredients that need heating or pre-dissolution before mixing

🔹 4. Automation & Control

- ✅ PLC/HMI Integration: Use a programmable logic controller with HMI for recipe control, dosing sequences, and real-time monitoring

- ✅ Load Cells: Monitor tank levels to ensure precise ingredient tracking and replenishment

🔹 5. Continuous Production Flow

- ✅ Ingredient Storage: Use stainless steel tanks with level sensors and hygienic pumps

- ✅ Automated Dosing: Controlled by the PLC, ingredients are fed directly into the mixer based on pre-set recipes

- ✅ Inline Mixing: The mixer continuously homogenizes and disperses ingredients in real time

- ✅ Final Dispersion: The finished liquid is transferred to the wet wipe impregnating system

🔹 6. Key Equipment Considerations

- ✅ Multi-Stage Mixing Chamber: Ensure high shear performance through a multi-stage design

- ✅ Sanitary Construction: Use pharmaceutical-grade stainless steel such as SS316L

- ✅ Scalability: Choose a mixer model that supports variable flow rates and production volumes

🔹 7. Optional Enhancements

- ✅ Inline Heating & Cooling: Integrate a jacketed mixer for temperature-sensitive ingredients

- ✅ CIP System: Add a Clean-In-Place system for fully automated cleaning and sanitization

By leveraging a well-designed inline mixer and automated dosing system, manufacturers can achieve a streamlined, hygienic, and efficient wet wipe production process—all while maintaining the flexibility to adapt formulations as needed.

Need Help Selecting Your Equipment?

Talk to our product expert today

PerMix is here to listen to your needs and provide sustainable solutions. Contact us to discover more.